What is the role of the vertical Taidexing machining center?

Release time:

2023-01-10 13:56

author:

The vertical Taidexing machining center is the main shaft bearing of Taidexing machining center arranged vertically on the operating platform. It is a multi-function CNC lathe with automatic tool change device, which is often used for flat-panel processing, small object grinding tools and small shells.

What is the role of the vertical Taidexing machining center?

The vertical Taidexing machining center is the main shaft bearing of Taidexing machining center arranged vertically on the operating platform. It is a multi-function CNC lathe with automatic tool change device, which is often used for flat-panel processing, small object grinding tools and small shells.

In order to use at least two three-axis linkage, generally three-axis linkage, and six-axis operating axis, in the process of NC boring machine can complete, screw and drilled screw drilling.

Taidexing machining center is a relatively high electromechanical integration product after workpiece clamping. It can automatically set the tool for different machining processes, and can complete a lonely process of drilling, cutting, hinge, screw teeth, etc. It reduces the tightening time of the workpiece, as well as the production and processing time of other auxiliary countermeasures and optimization equipment, so as to facilitate the production and processing of more complex and high-precision forms, and the economic effect of frequent replacement of parts.

Taidexing machining centers are classified into vertical and universal Taidexing machining centers according to the position relationship between the spindle bearing and the operating platform.

(1) Horizontal Taidexing machining center: refers to the CNC machine arranged parallel to the main shaft bearing and the worktable, which is suitable for the production and processing of box-shaped parts.

(2) Vertical Taidexing machining center: it is arranged as a vertical spindle bearing on the table, which is generally used for shell-type abrasive flat plate type to solve complex parts.

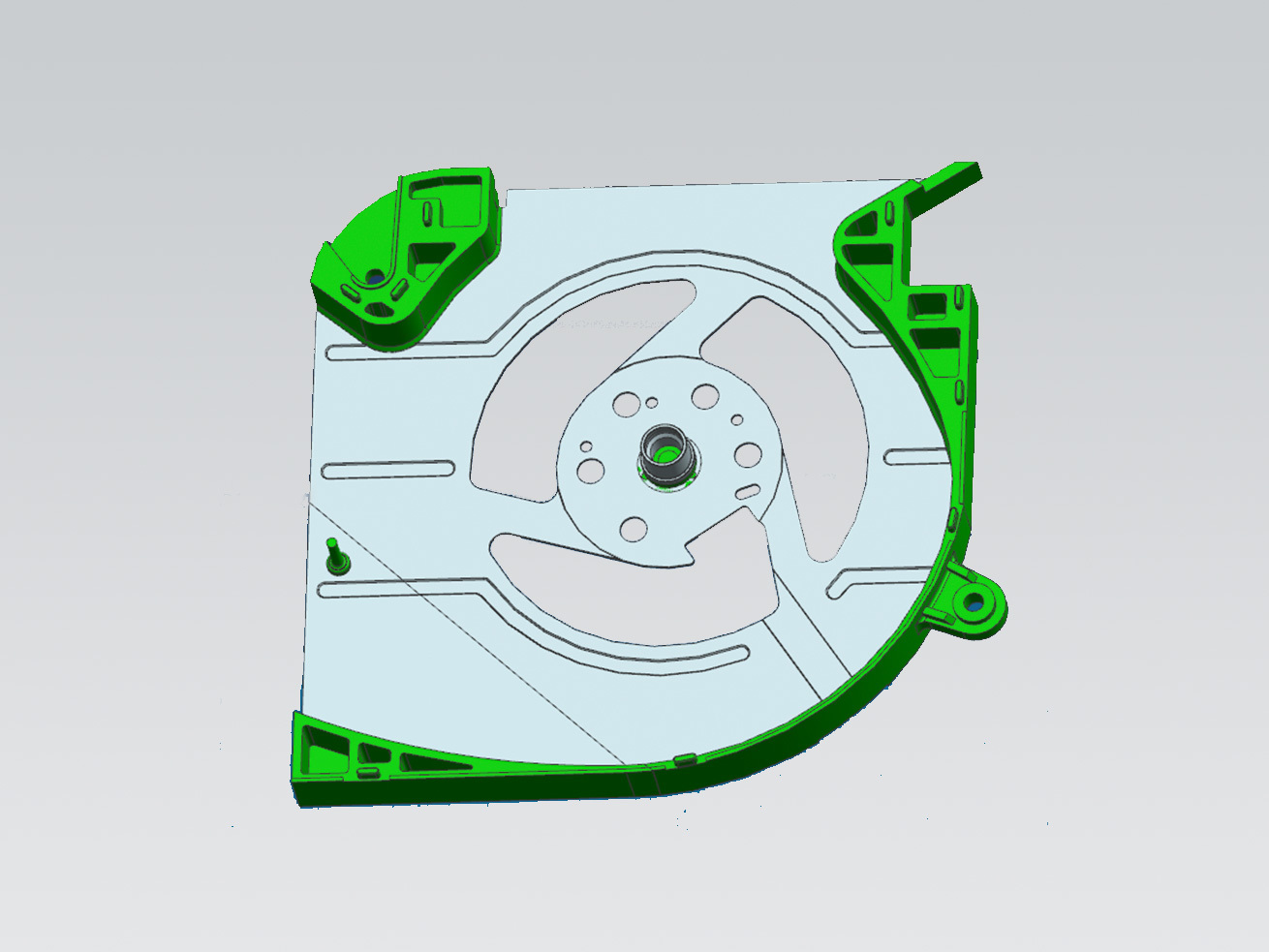

(3) The core of universal machining and manufacturing is to change the spindle bearing production and processing rotation with complicated angle of view inclined plane in connection with the axis centerline table operation. It is suitable for surface centrifugal impeller grinding tools for machining motor rotors as product workpieces, and cutting tools for complex indoor space.

What are the structures of the vertical Taidexing machining center?

1. Basic parts: basic parts refer to the bed casting. It is composed of bed body, stand and operation platform; It is the basic component of the CNC Taidexing Machining Center, most of which are cast iron parts. Because of the static load test and drilling load that it must be able to bear when it gradually runs. Therefore, the bending rigidity of its bed castings is very high, and they are very important components for CNC production and processing.

2. Main shaft bearing components: vertical Taidexing machining center is composed of main shaft motor, main shaft box, main shaft bearing, main shaft support point and other components;

3. Automatic control system: CNC machine tool is composed of CNC equipment, programmable logic controller, servo drive equipment and its motor;

4. Servo control system: the function of the servo control system is to convert the signals from the numerical control device into the movement of moving parts of the numerical control lathe in the future. Its characteristics are one of the important factors to measure the dimensional accuracy, surface quality and productivity of the numerical control lathe;

5. Automatic tool change device: it is composed of CNC tool, robot, transmission mechanism and other parts;

6. Full-automatic tray replacement equipment: some CNC Taidexing machining centers are equipped with two automatic exchange product tray to further reduce the non-chip time, one is assembled on the operating platform for reprocessing, the other is located outside the operating platform to carry out product workpiece handling, which can reduce auxiliary time and improve production efficiency;

7. Intelligent auxiliary system: including lubrication device, cooling system, chip removal device, safety device, hydraulic press and any monitoring system. It plays a key role in ensuring the efficiency, accuracy and stability of the machining center.

10

2023

-

01

How to polish the die casting of security camera

The appearance technology of the security camera die casting is rich, and the appearance effect of the security camera die casting is very beautiful. How to polish the security camera die-casting parts? Now let's have a look at the relevant content. I believe you can have a more detailed understanding.

04

2025

-

05

Unlocking the Potential of Brass Stamping Dies: A Comprehensive Guide

Brass stamping dies are essential tools in the manufacturing and machining sector, particularly in the production of metal components through stamping processes. These dies are specifically designed to shape and cut brass materials into precise forms, making them invaluable for various applications in industries such as automotive, electronics, and consumer goods. Understanding the significance of

03

2025

-

05

Unlocking Creativity: How Free Sample Brass Stamping Dies Can Transform Your Projects

Unlocking Creativity: How Free Sample Brass Stamping Dies Can Transform Your Projects Table of Contents 1. Introduction to Brass Stamping Dies 2. The Importance of Free Sample Brass Stamping Dies 3. How Brass Stamping Dies Work 4. Advantages of Using Brass Stamping Dies 4.1 Cost-Effectiveness 4.2 Precision and Quality 4.3 Versatility in Design 5. Applications of Brass Stamping Dies 5.1 Automotive