How does the vertical Taidexing machining center produce and process parts?

Release time:

2023-01-10 13:54

author:

The operating system of the vertical machining center is the system software that uses the computer system to control the production and processing functions and complete the control of the standard value.

How does the vertical Taidexing machining center produce and process parts?

The operating system of the vertical machining center is the system software that uses the computer system to control the production and processing functions and complete the control of the standard value. According to the management program stored in the electronic computer memory, the CNC machine tool implements all or part of the marked value operation, and is equipped with communication interface and special computer software for servo drive device. The platform is composed of CNC lathe program, input device, export device, electronic computer numerical control device CNC device, programmable logic control board PLC, spindle bearing drive mechanism and tool drive mechanism including detection system.

The key of CNC system software is CNC equipment. Because of the use of electronic computers, the system software has software tools, and PLC replaces the traditional machine tool electrical logic control equipment, so that the operating system is more sophisticated, its coordination ability, practicality, and stability are stronger, and it is convenient to complete the complex functions of CNC machine tools, application, maintenance and maintenance are also convenient, and it has the function of connecting with the upper computer software and carrying out remote communication.

CNC has good softness and high automation level, especially suitable for the production and processing of curves with complicated contour shapes, inclined parts, and the production and processing of complicated shells and prismatic parts with many holes and grooves. Under the premise of multiple products and small batches, the application of CNC machine tool processing can obtain relatively high economic benefits. Therefore, when planning the turning process of parts, we should not only follow the CNC lathe with good processing flexibility and high automation level, especially suitable for the production and processing of complicated contour curves, inclined parts, as well as shell and prismatic parts with many holes and grooves. Under the premise of multiple products and small batches, the application of CNC lathe processing can obtain relatively high economic benefits.

What is the main purpose of CNC vertical Taidexing machining center?

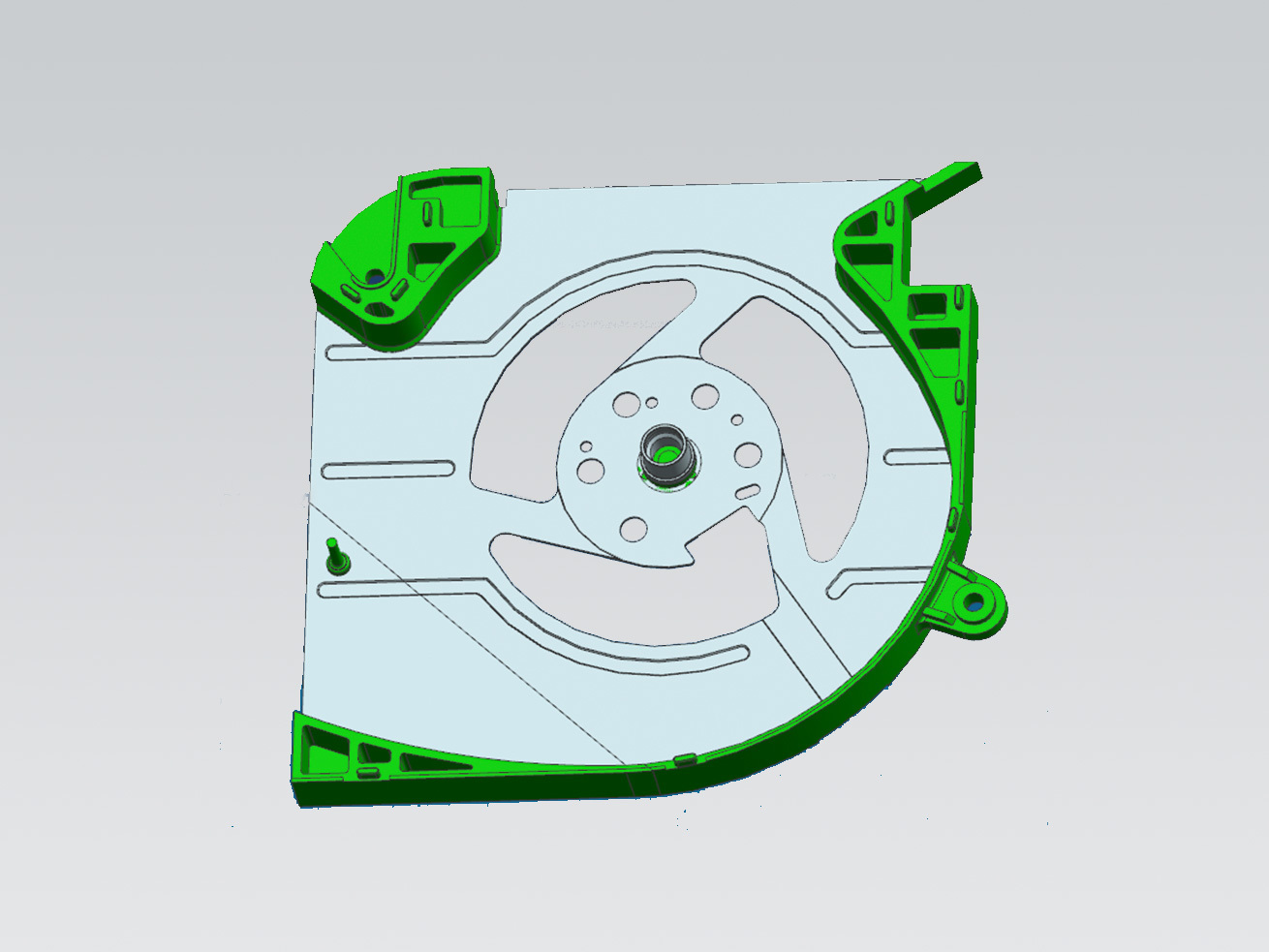

The vertical Taidexing machining center refers to the Taidexing machining center set vertically between the center line of the main shaft bearing and the operating platform. It is generally applicable to the production of complex parts such as plates, discs, abrasive tools and small and medium-sized shells. Taidexing machining center can complete the processes of milling, boring, milling, tapping and drilling screw teeth. The vertical Taidexing machining center Z is mostly three-axis and two-linkage, which can generally complete three-axis and three-linkage. The relative height of the upright pole of the vertical Taidexing machining center is very limited, and the production scope of shell products is minimized, which is also the defect of the vertical Taidexing machining center. However, the clamping and precise positioning of product workpiece are convenient; The movement track of the NC blade is easy to observe and check, and the program debugging, checking and accurate measurement are convenient, which can find problems as early as possible and carry out shutdown processing and modification; The refrigeration standard is easy to create, and the cutting oil can directly reach the CNC blade and the production surface. The three vertical coordinates are consistent with the Cartesian plane coordinates. I feel that the visualization is consistent with the angle of the sample drawing, and the cutting is easy to discharge and burst, so as to prevent scratching the production and processing surface. Compared with the corresponding horizontal Taidexing machining center, the structure is compact, the total area is relatively small, and the price is relatively low.

The structure of the small and medium-sized vertical Taidexing machining center is basically the same as that of the CNC machine tool, and the manufacturing process is relatively similar, but the two will also be different. CNC with automatic tool change device and numerical control tool has fully automatic tool setting function, which can be repaired according to the numerical control tool used in production and processing. In general, this equipment can be used to re-process different types of process flow of product workpiece with arbitrary tool setting.

10

2023

-

01

How to polish the die casting of security camera

The appearance technology of the security camera die casting is rich, and the appearance effect of the security camera die casting is very beautiful. How to polish the security camera die-casting parts? Now let's have a look at the relevant content. I believe you can have a more detailed understanding.

04

2025

-

05

Unlocking the Potential of Brass Stamping Dies: A Comprehensive Guide

Brass stamping dies are essential tools in the manufacturing and machining sector, particularly in the production of metal components through stamping processes. These dies are specifically designed to shape and cut brass materials into precise forms, making them invaluable for various applications in industries such as automotive, electronics, and consumer goods. Understanding the significance of

03

2025

-

05

Unlocking Creativity: How Free Sample Brass Stamping Dies Can Transform Your Projects

Unlocking Creativity: How Free Sample Brass Stamping Dies Can Transform Your Projects Table of Contents 1. Introduction to Brass Stamping Dies 2. The Importance of Free Sample Brass Stamping Dies 3. How Brass Stamping Dies Work 4. Advantages of Using Brass Stamping Dies 4.1 Cost-Effectiveness 4.2 Precision and Quality 4.3 Versatility in Design 5. Applications of Brass Stamping Dies 5.1 Automotive