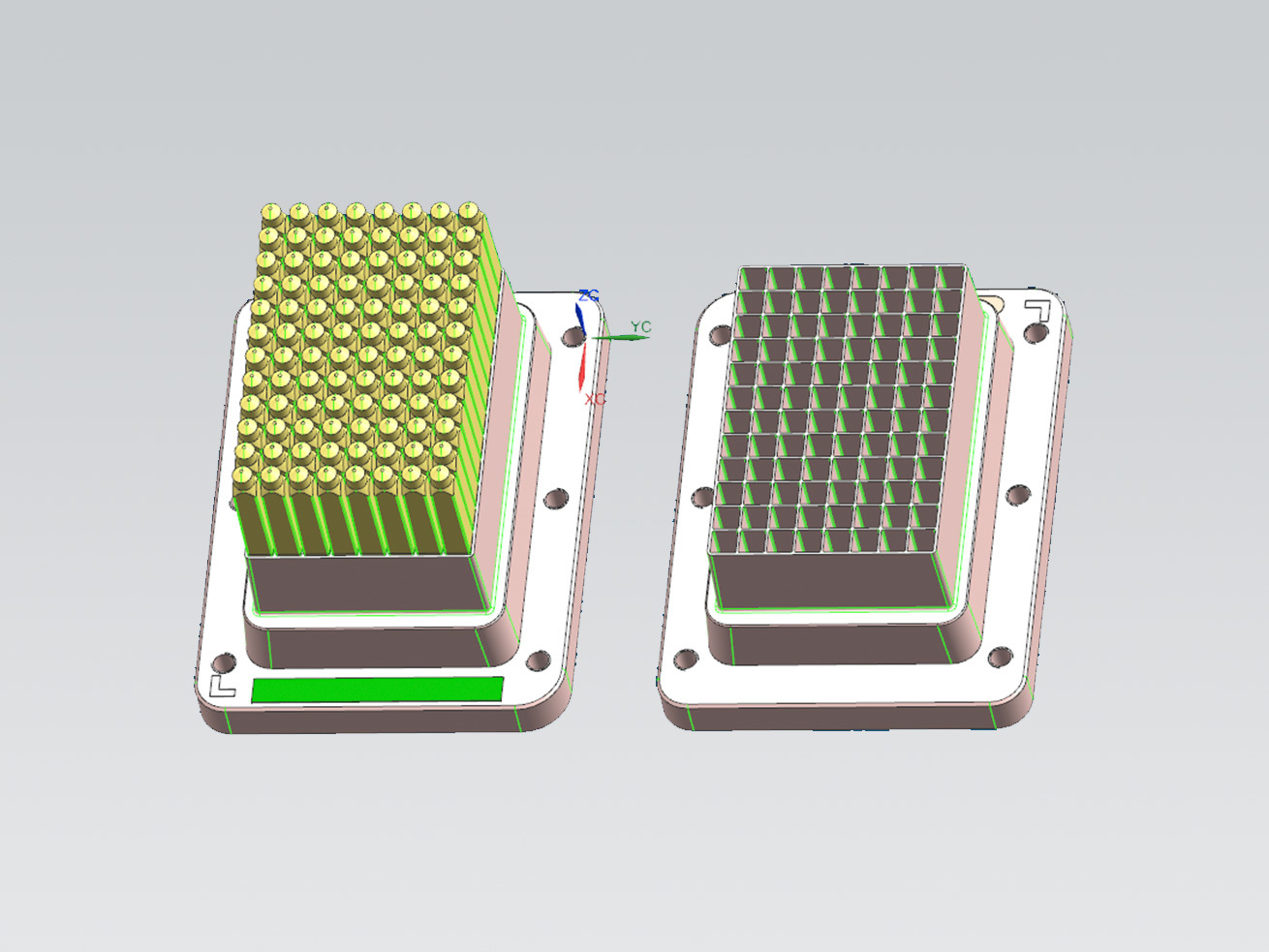

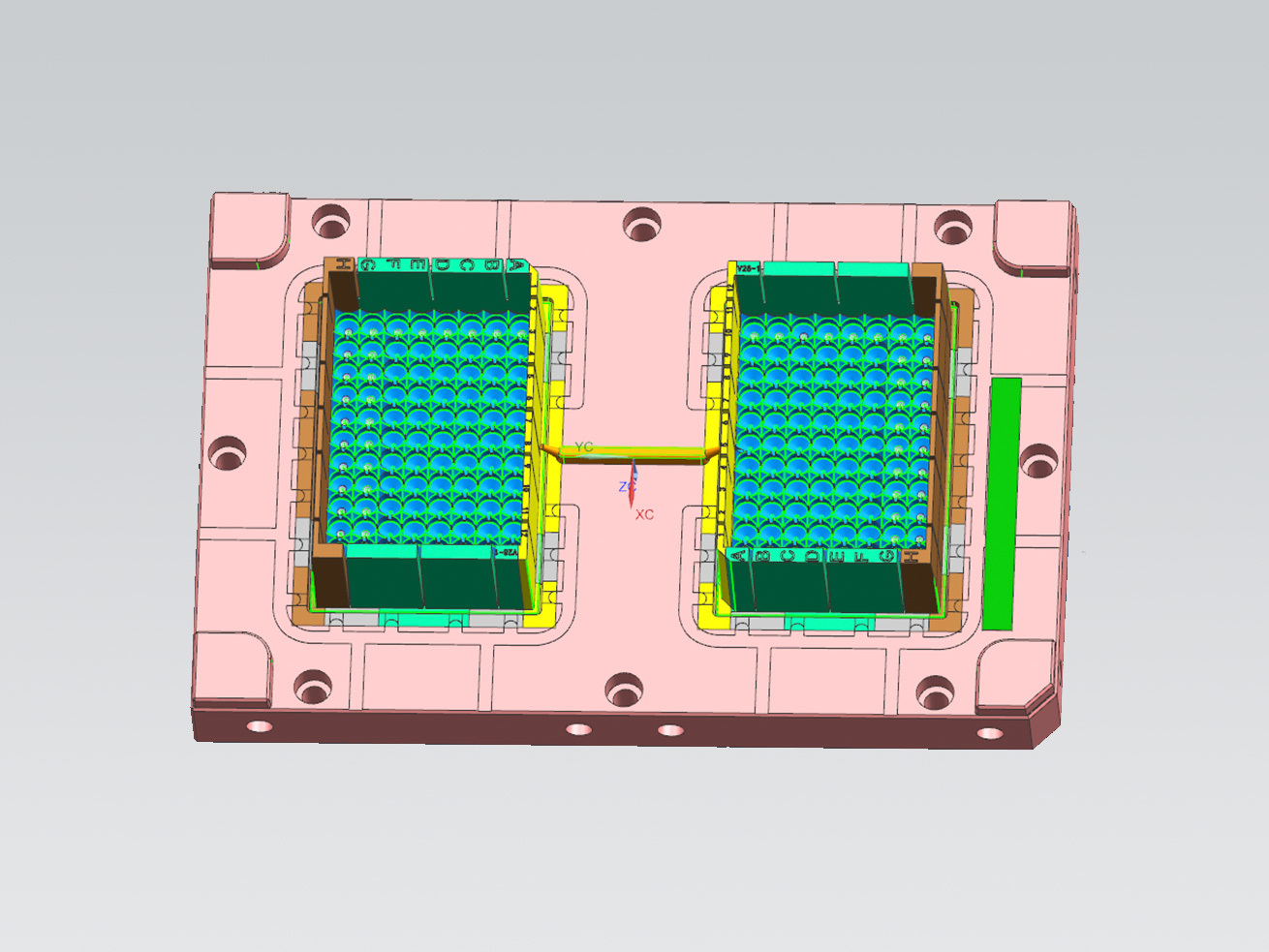

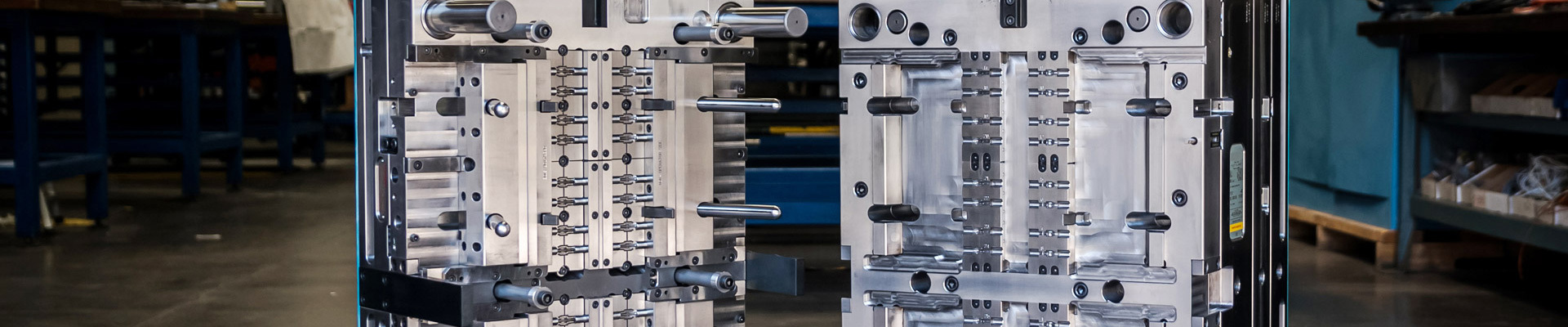

Medical device mold 2

Main features Compared with the traditional machining methods of turning, milling and drilling, wire cutting has its own characteristics:

Category:

Medical device mold

key word:high temperature

TEL:

Medical device mold 2

Main features

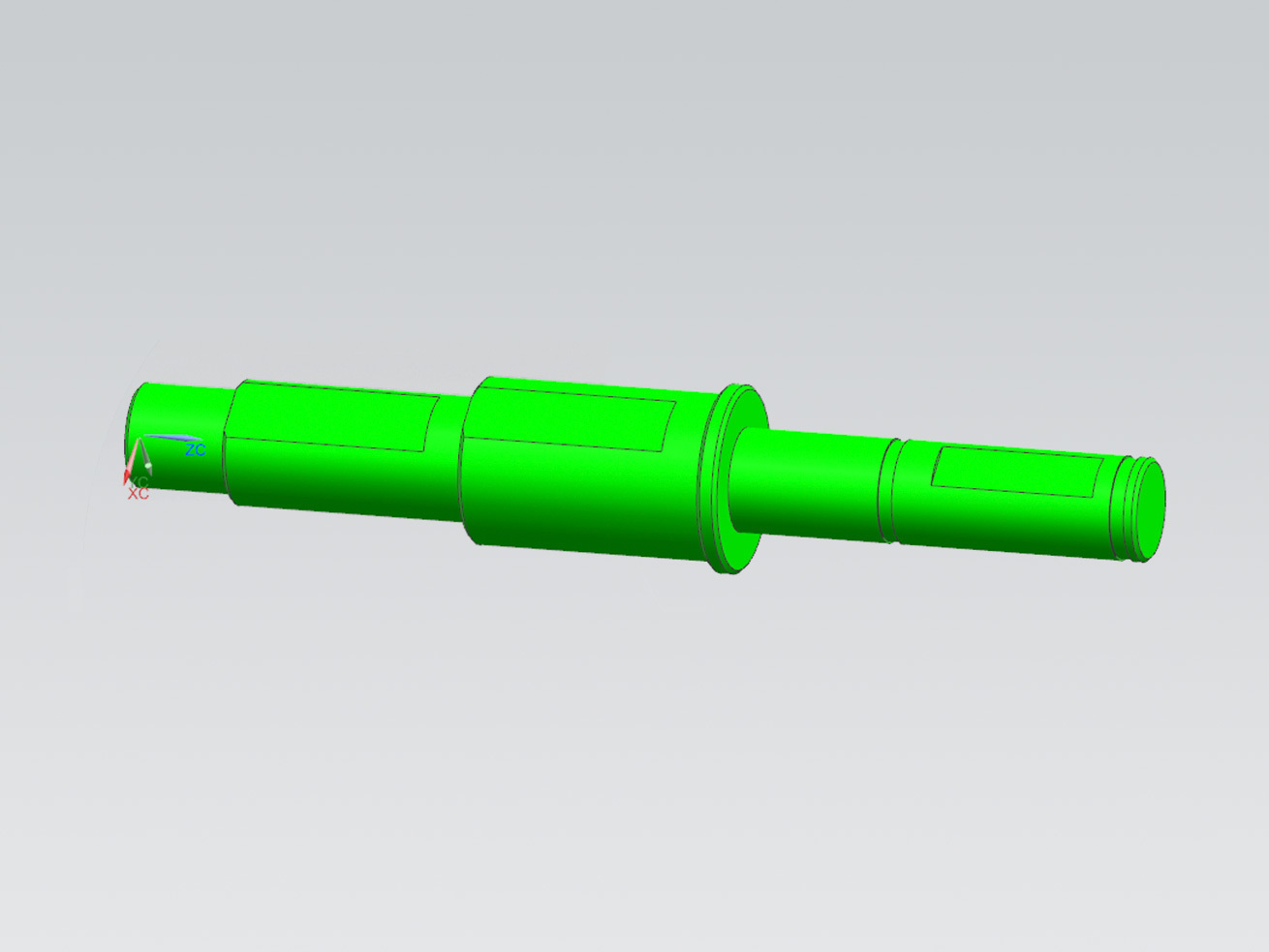

Compared with the traditional machining methods of turning, milling and drilling, wire cutting has its own characteristics:

(1) Directly use 0.03-0.35mm metal wire as electrode without special shape, which can save the design and manufacturing costs of electrode;

(2) No matter how hard the workpiece material is, as long as it is conductor or semiconductor material, it can be processed, and the electrode wire loss is small, and the processing accuracy is high;

(3) It is suitable for the processing of small batches of parts with complex shapes, single pieces and trial products, and the processing cycle is short;

(4) In WEDM, the electrode wire and the workpiece are not in direct contact, and the effect between them is very small, so the deformation of the workpiece is small, and the electrode wire and fixture do not need too high strength;

(5) The working fluid is water-based emulsion with low cost and no fire;

(6) It is not suitable for processing large quantities of parts with simple shapes, nor for processing non-conductive parts.

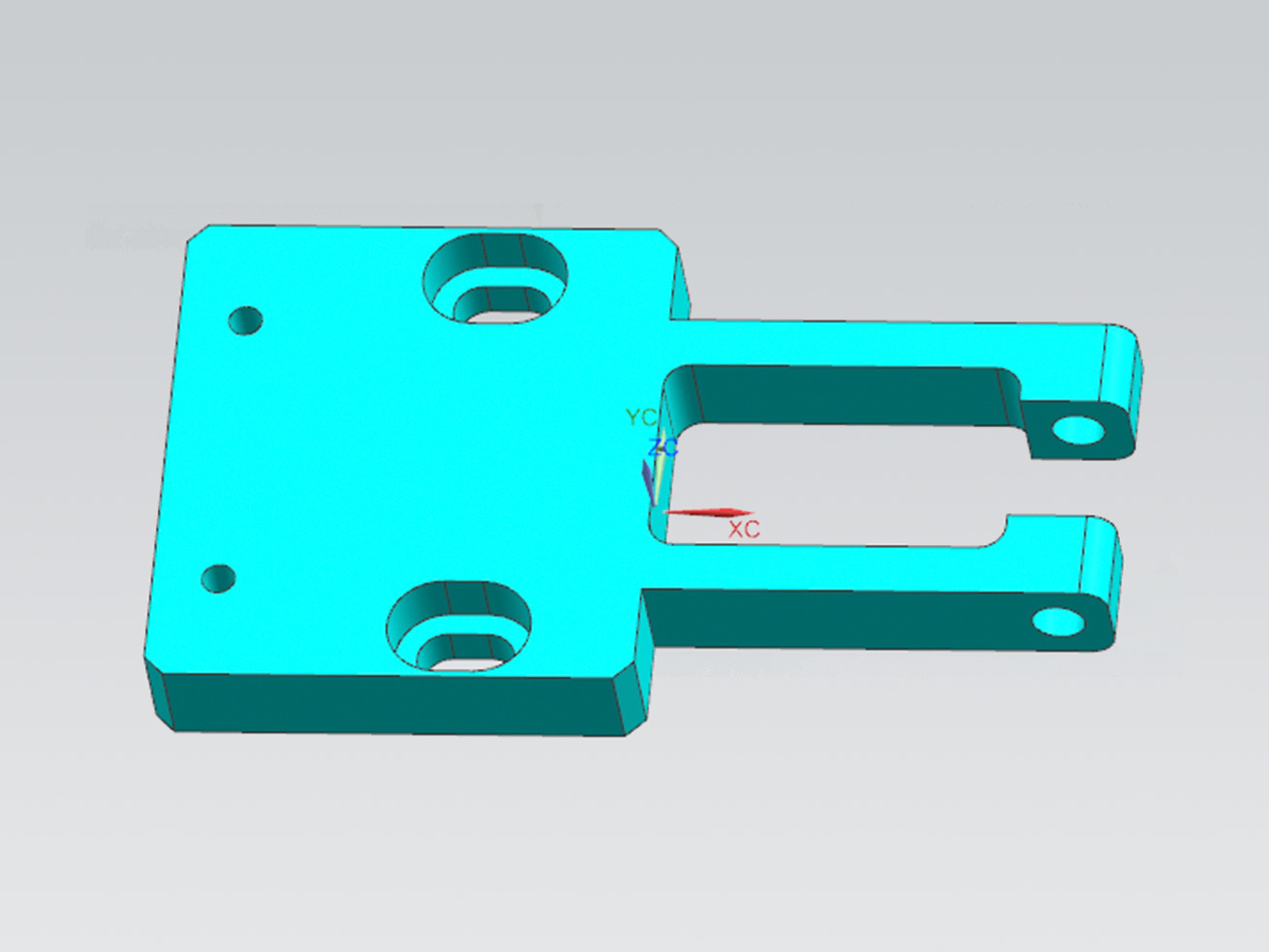

Automatic non-standard parts 2

Wire cutting is the abbreviation of wire cutting, which refers to a processing method.

Automatic non-standard parts 6

There are precision CNC equipment such as precision slow wire, CNC amplifier and machining center

philosophy of "quality first, excellence". We strive to provide customers with high-quality services

Main features Compared with the traditional machining methods of turning, milling and drilling, wire cutting has its own characteristics:

ONLINE MESSAGE

Filling in your phone and email information will help us to contact you in a timely manner and resolve your concerns as soon as possible.

Note: Items marked with * are mandatory, thank you!